Industrial Woodworking Machinery

high-performance woodworking machines

High Quality Products

Experienced Technicians

Years of Experience

Over 300 spare parts

Why Choose Leadermac UK?

- Technical Support

- Installation & Commissioning

- Spare Parts

- Repair & Maintenance

- Used & Reconditioned Machinery

Technical Support: Maximizing the Performance of Your Woodworking Machinery

At Leadermac UK, we provide comprehensive technical support to help you get the best performance from your industrial woodworking machinery. Whether you’re using a spindle moulder, rip saw, or a full auto planing moulder line, our dedicated team ensures your machinery operates efficiently, minimizing downtime and maximizing productivity.

Dedicated Support Line: Our expert technical support team is available to assist with issues such as troubleshooting machine problems, optimizing settings, and providing maintenance advice. We specialize in woodworking machinery, ensuring that everything from your 4-sided moulder to your knife grinding machine is running smoothly.

Comprehensive Resources: Gain access to detailed technical documentation, user manuals, and video guides to help you resolve issues quickly. Whether it’s maintaining a spindle moulder or servicing spare parts for a multi rip saw, our resources are designed to keep your production line operating at peak performance.

On-Site Assistance: For more complex issues, our technicians can visit your site to provide hands-on support. From industrial woodworking machinery spare parts replacement to solving technical problems with your planer or industrial moulder, our on-site team ensures your machinery is back to full working order swiftly.

Contact Leadermac UK today for exceptional technical support that keeps your industrial woodworking machinery running at its best.

Installation and Commissioning: Precision Setup for Your Woodworking Machinery

At Leadermac UK, we take pride in providing comprehensive installation and commissioning services for your industrial woodworking machinery. Whether you’re setting up a 4-sided moulder, spindle moulder, or multi rip saw, our experienced service technicians and field engineers ensure that your equipment is installed to the highest standards, maximizing productivity and minimizing downtime.

Detailed Installation: We oversee the entire installation process, from delivery to final setup. Our team ensures that each component of your machinery, whether it’s an industrial planer or knife grinding machine, is perfectly aligned and ready for operation. We focus on precision to ensure your machinery operates seamlessly from the start.

Expert Commissioning: After installation, our team performs thorough testing and fine-tuning of your equipment to guarantee optimal performance. We ensure that your industrial moulder or auto planing moulder line meets all operational standards and is fully optimized before it goes into full production.

Operator Training: To ensure safe and effective operation, we provide comprehensive training for your team. This includes hands-on training sessions for operating and maintaining machinery like spindle moulders and multi rip saws, so your staff is fully prepared to handle the equipment.

This service is designed to ensure that your new woodworking machinery delivers the best possible performance from day one, minimizing any downtime and optimizing your production efficiency.

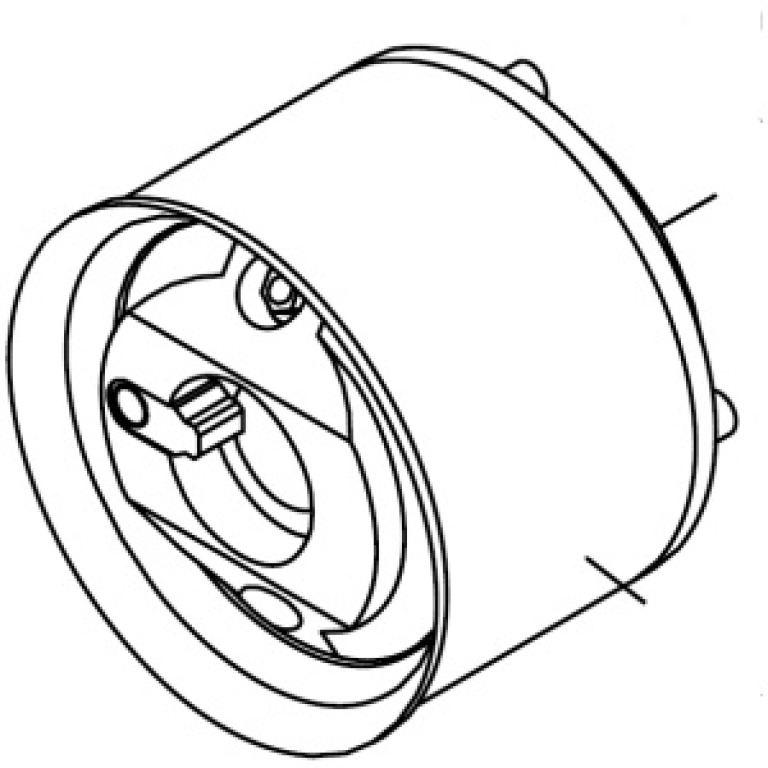

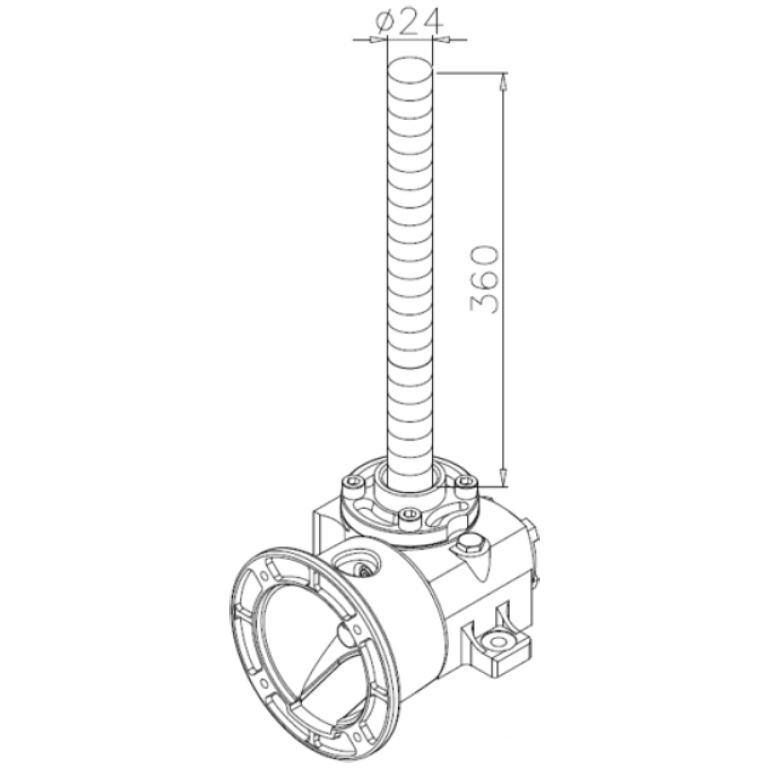

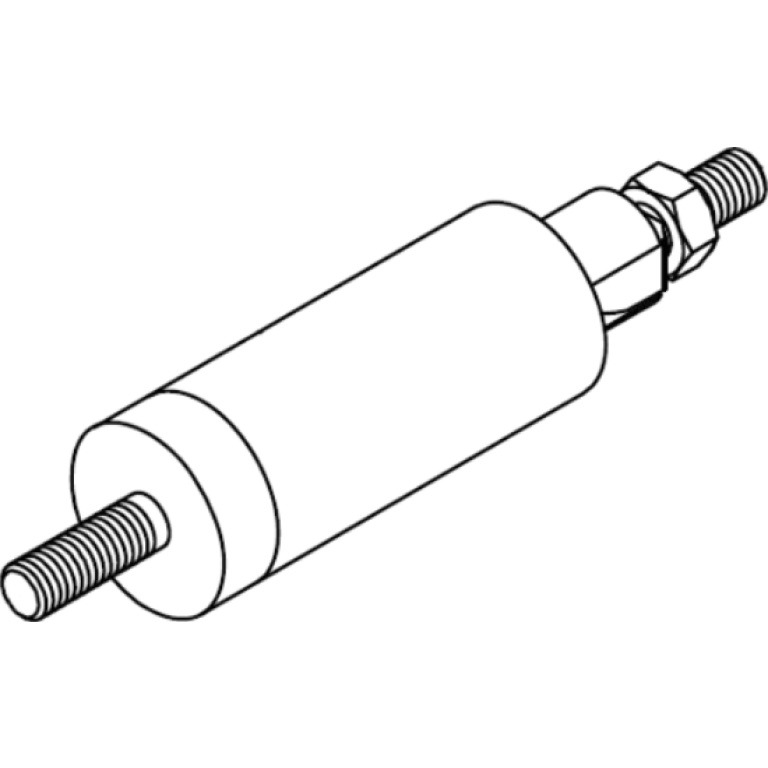

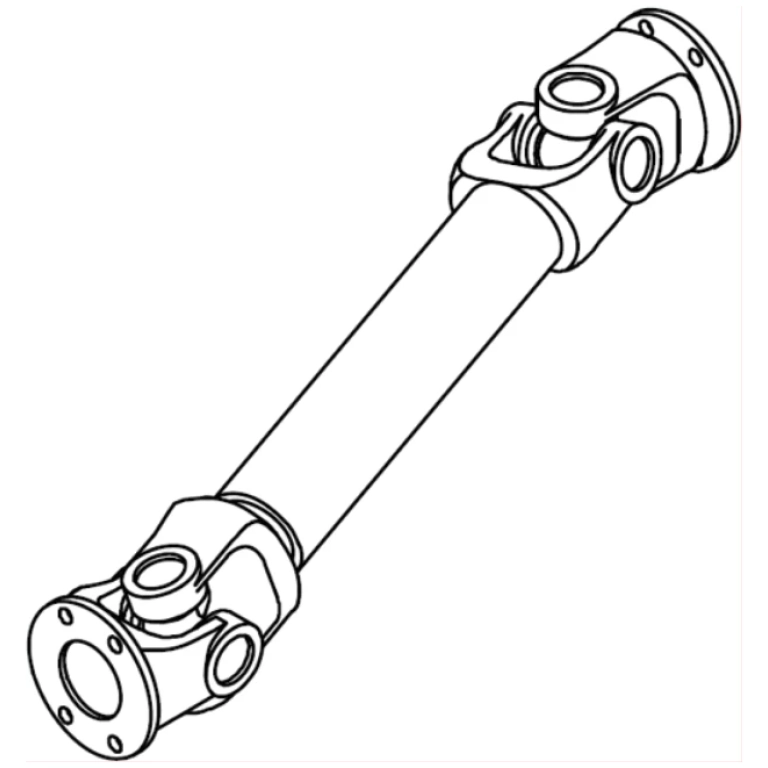

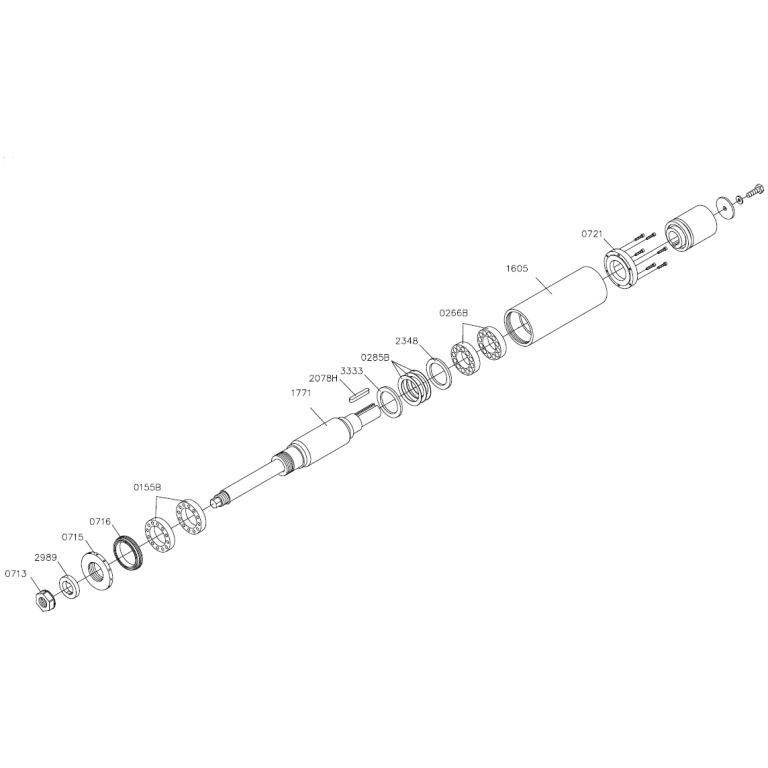

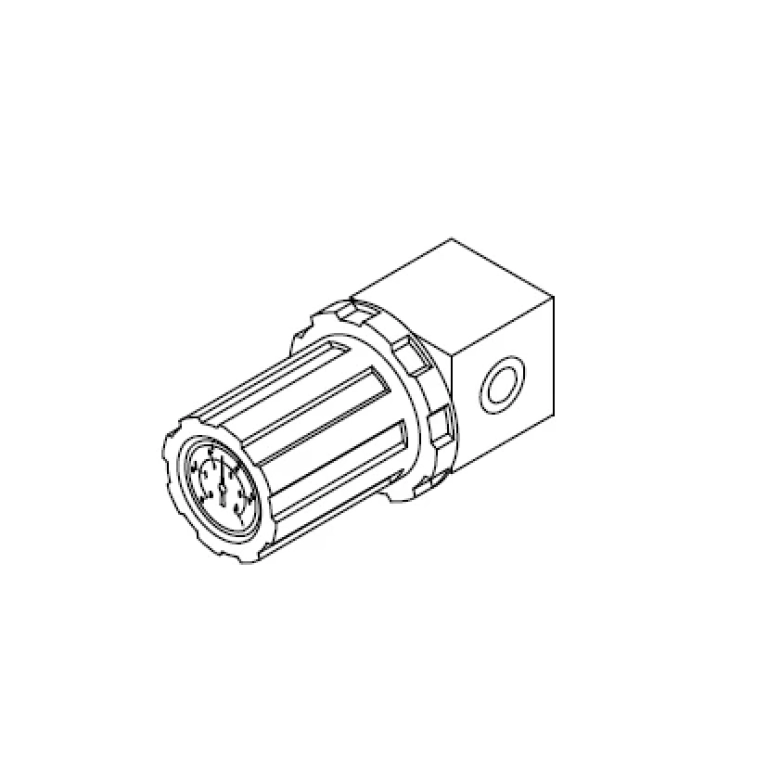

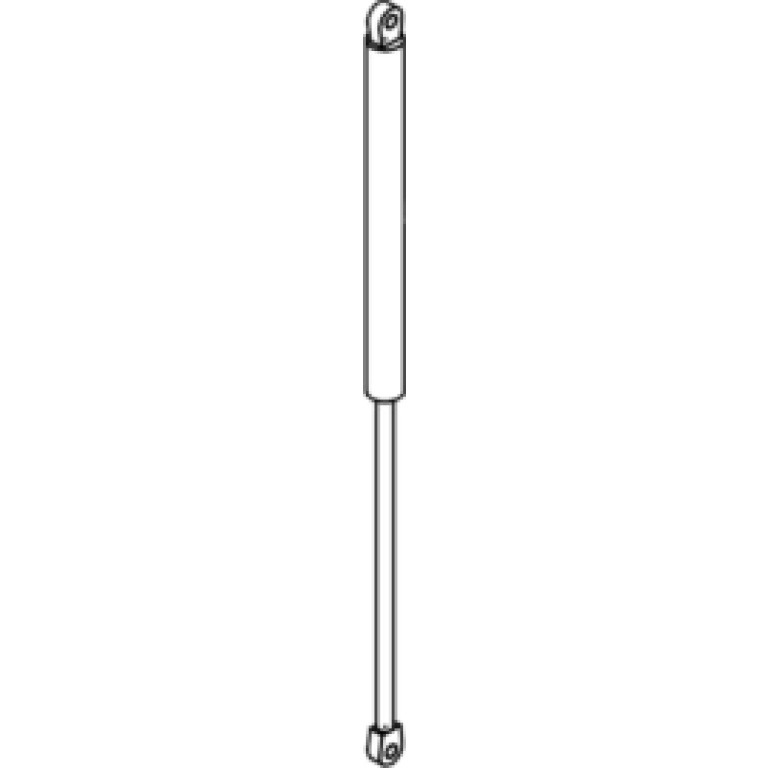

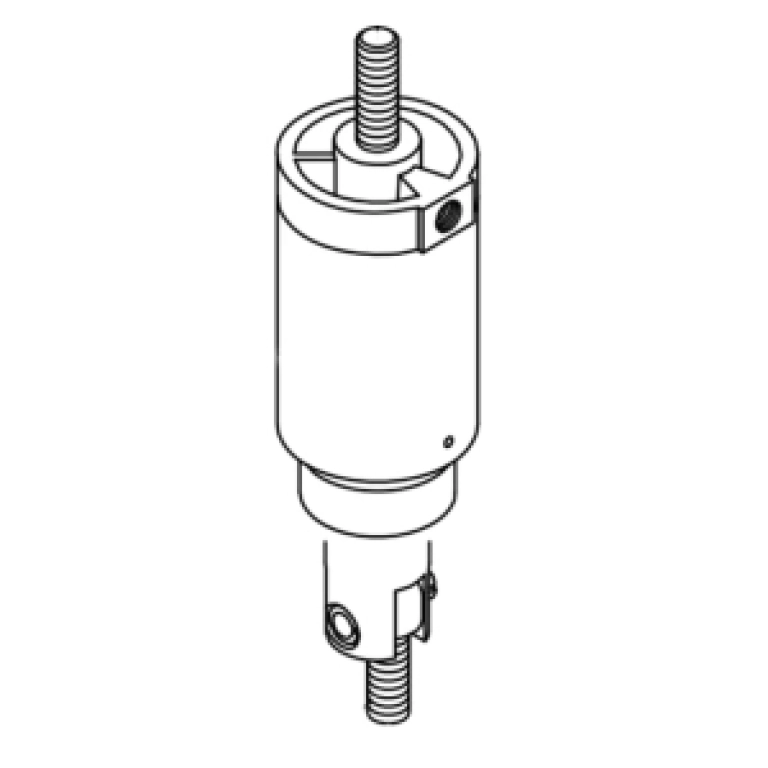

Spare Parts: Keeping Your Industrial Woodworking Machinery Operational

At Leadermac UK, we understand that having the right spare parts for your industrial woodworking machinery is essential to keeping your equipment in top working condition. That’s why we offer a comprehensive range of genuine spare parts designed to minimize downtime and ensure maximum productivity.

Extensive Stock: We maintain a large inventory of spare parts for industrial woodworking machinery, including both current and legacy models. Whether you need 4-sided moulder spare parts, spindle moulder replacement components, or multi rip saw parts, our stock is ready for fast dispatch.

Easy Ordering: Ordering the right parts for your woodworking machinery is easy through our website or by contacting our parts department directly. Our team will help you find the correct replacement parts, whether it’s for a knife grinding machine or an industrial planer.

Fast Delivery: With most parts in stock, we offer fast delivery of woodworking machinery spare parts, ensuring your equipment gets back to full operation as soon as possible. From 4-sided moulder spare parts to spindle moulder components, we prioritize quick shipping to reduce downtime.

Order your genuine spare parts from Leadermac UK today and keep your industrial woodworking machinery running smoothly.

Repair and Maintenance: Ensuring Peak Performance for Your Woodworking Machinery

Regular maintenance and timely repairs are crucial for maintaining the longevity and efficiency of your industrial woodworking machinery. At Leadermac UK, we provide comprehensive repair and maintenance services for all types of woodworking machinery, including 4-sided moulders, spindle moulders, and industrial planers, ensuring your equipment remains in top working condition.

Rapid Response Repairs: Our UK-wide network of engineers is ready to respond quickly to repair requests, helping to minimize the impact of unexpected breakdowns on your production schedule. Whether it’s your 4-sided moulder or a multi rip saw, our team ensures rapid repairs to get your machinery back in operation as soon as possible.

Preventative Maintenance: To help avoid costly downtime, we offer tailored preventative maintenance services designed to meet the specific needs of your woodworking machinery. Our scheduled maintenance services are aimed at identifying and resolving issues before they arise, ensuring that your spindle moulder, knife grinding machine, or any other machine continues running smoothly and efficiently.

Expert Technicians: Leadermac UK’s technicians are highly trained and experienced in servicing all Leadermac equipment. Using genuine spare parts for woodworking machinery and the latest tools, our technicians ensure that every repair is performed to the highest standard. Whether it’s a 4-sided moulder repair or routine servicing for an industrial moulder, we guarantee professional and reliable results.

Keep your production on track with Leadermac UK’s expert repair and maintenance services, ensuring your industrial woodworking machinery operates at peak performance.

Used and Reconditioned Woodworking Machinery: High-Quality Equipment at a Fraction of the Cost

At Leadermac UK, we offer a select range of used and fully reconditioned woodworking machinery, providing a cost-effective solution for businesses looking for reliable equipment without the expense of purchasing new. Our reconditioned machinery goes through a rigorous refurbishment process, ensuring high quality and durability, but due to this, availability is often extremely limited.

Limited Inventory: Each piece of used woodworking machinery is carefully selected and undergoes thorough testing to meet our strict quality standards. From reconditioned 4-sided moulders to industrial planers, we ensure that every machine is meticulously refurbished, but because of the detailed process, only a limited number of machines are available at any time.

Quality Guaranteed: Our expert technicians fully inspect, repair, and upgrade each machine, ensuring it performs like new. Whether it’s a reconditioned spindle moulder or a multi rip saw, you can trust that our used woodworking machinery will deliver reliable, high-performance results—at a fraction of the cost of new equipment.

First-Come, First-Served: Due to high demand and the limited availability of our reconditioned woodworking machinery, we recommend acting quickly if you see a machine that fits your needs. These machines are sold on a first-come, first-served basis, and our inventory is frequently updated as machines are refurbished and sold.

Contact Leadermac UK today to check availability and secure one of our limited reconditioned woodworking machines before they’re gone.

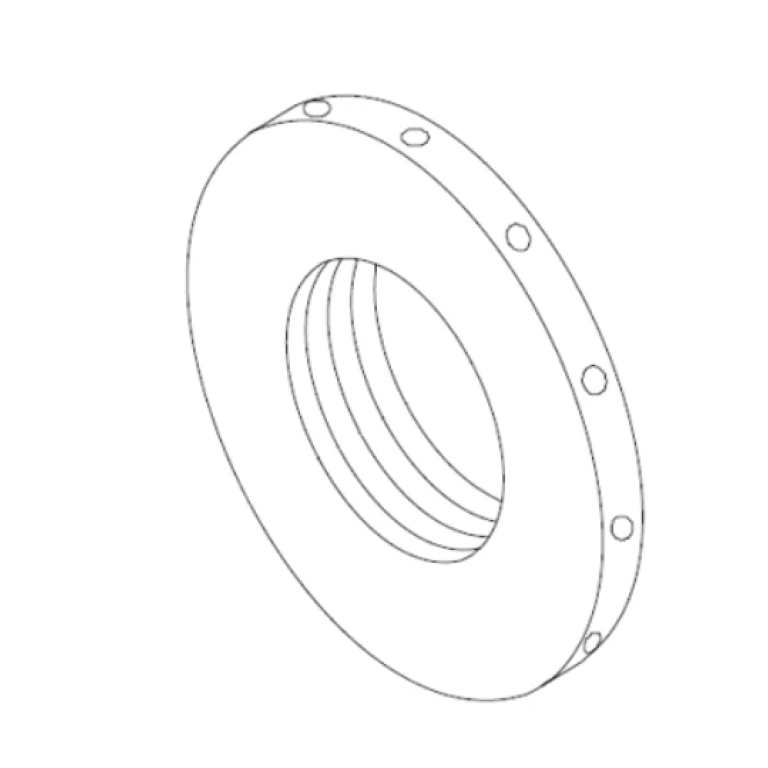

Our parts

About Us

About Leadermac UK: Revolutionizing Woodworking with Precision, Durability, and Innovation

At Leadermac UK, we are dedicated to transforming the woodworking industry through our state-of-the-art woodworking machinery. With a focus on precision, durability, and innovation, we provide high-performance solutions for woodworking professionals and industrial users alike. Backed by over 20 years of experience, Leadermac has evolved from a pioneering manufacturer into a global leader in woodworking machinery.

Our mission has always been clear: to empower craftsmen and industrial operators with reliable, efficient machines that elevate their work. From 4-sided moulders to spindle moulders, our equipment is designed to meet the diverse and evolving needs of the woodworking industry.

Get in Touch with Us

Need more information or ready to make an inquiry? At Leadermac UK, we’re here to help with all your woodworking machinery needs. Whether you’re interested in our new or reconditioned woodworking machines, need genuine spare parts for your 4-sided moulder or spindle moulder, or require expert technical support, we’re just a click away.

UK-Based Support: Serving businesses across the UK, we provide fast and reliable assistance to keep your machinery running smoothly, from installation and commissioning to repair and maintenance services.

Contact us today to discuss your requirements and discover how Leadermac UK can deliver the perfect solution for your business.