Feed Rollers

High-Performance Feed Rollers for Woodworking Machines

Feed Rollers for Moulders & Planers

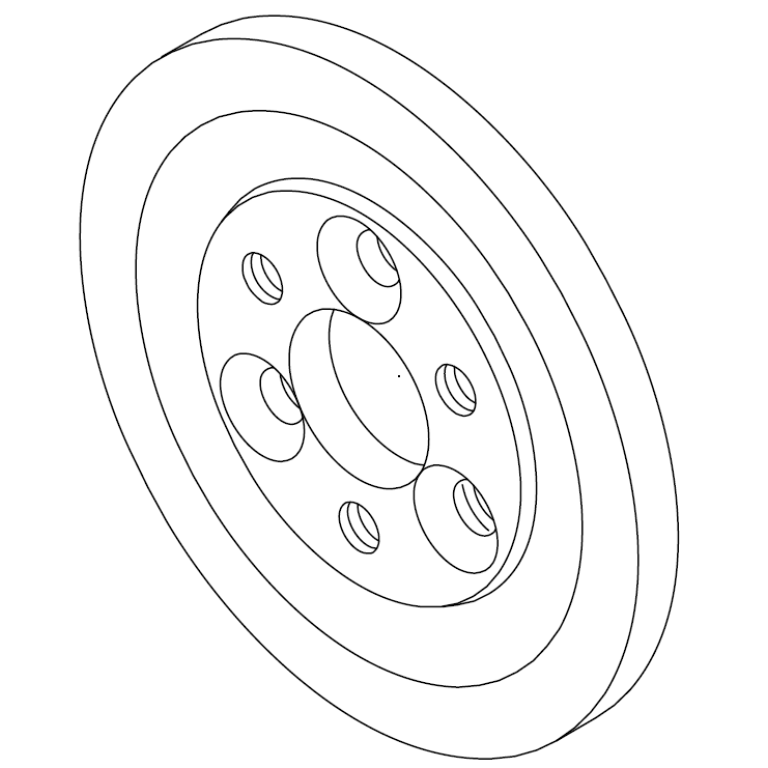

Feed rollers are the driving force behind every moulder and planer — gripping, guiding, and feeding timber smoothly through the machine with precision and control. Whether you’re producing fine mouldings, flooring profiles, or structural components, high-quality rollers are essential to maintain consistent feed pressure, surface finish, and dimensional accuracy.

At Leadermac UK, we supply a complete range of feed rollers for woodworking machinery, including steel, rubber, and wet-wood rollers for both infeed and outfeed applications. Each roller is engineered to deliver maximum grip, long service life, and perfect balance — ensuring smooth production even in demanding, high-throughput environments.

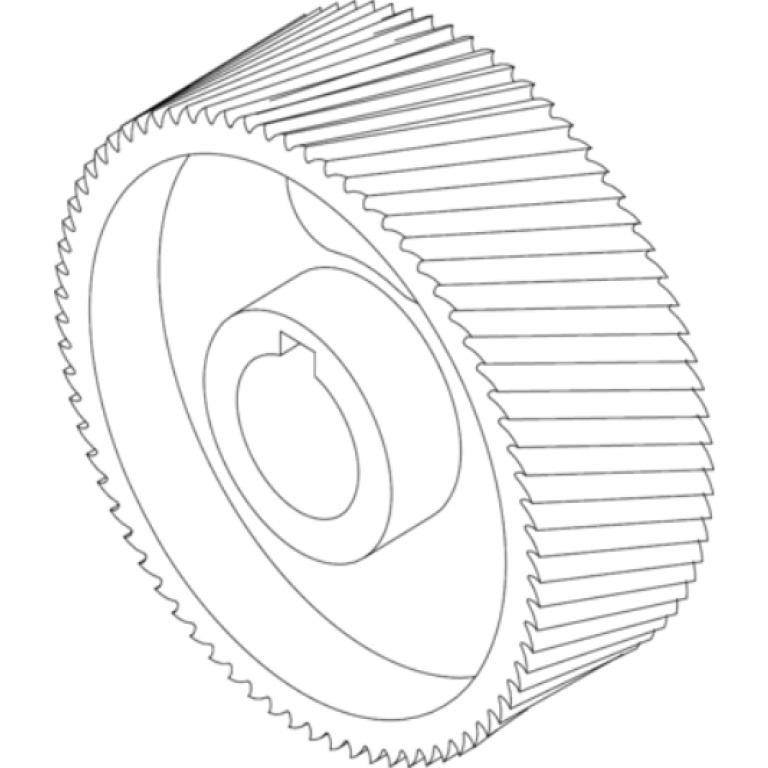

- Steel Feed Rollers – Built for durability and torque transfer, steel rollers are ideal for rough timber or heavy stock removal. Available in knurled, smooth, or spiral-grooved finishes to suit different feed pressures and surface needs.

- Rubber Feed Rollers – Designed for delicate finishing operations, rubber rollers protect the timber surface while maintaining reliable traction. Choose from standard and high-grip compounds depending on feed speed and wood type.

- Wet-Wood Feed Rollers – Specially formulated rubber compounds prevent slipping on damp timber, commonly used in softwood and green-timber machining.

All rollers are precision-machined for exact bore diameters, keyways, and widths, ensuring seamless compatibility with Leadermac, Weinig, SCM, Küpfer, CASADEI, and other major moulder brands.

Our feed rollers are manufactured by trusted European partners using premium materials and controlled curing or machining processes. Every roller is balanced and inspected for concentricity to eliminate vibration and extend bearing life. Standard diameters range from 120 mm to 160 mm, with common bores 35 mm – 40 mm, though custom sizes can be produced on request. For ongoing production, we can stock repeat orders for fast UK dispatch, helping you minimise downtime and maintain just-in-time supply.

As a specialist in woodworking machinery parts and tooling, Leadermac UK supports workshops, joineries, and production lines nationwide. Whether you need a single replacement roller or a complete re-stock for multiple moulders, our team can help you identify the correct fit based on diameter, bore, surface type, and machine model.

Browse our full selection below, or contact Leadermac UK for expert sizing advice and fast quotations on standard or custom feed rollers.

Our parts

Learn about our feed rollers

The best material depends on your machining process and timber type. Steel rollers are ideal for high-pressure feeding and rough timber. Rubber rollers protect the surface on finishing passes, while wet-wood rollers offer grip on damp or green timber. If you’re unsure, our team can recommend the right balance of grip, durability, and surface protection for your setup.

In many cases, yes. We can arrange rubber re-covering and surface re-profiling for worn rollers to restore grip and alignment. However, rollers with damaged cores or shafts are better replaced outright for safety and accuracy. Send us a photo or dimensions and we’ll advise the most cost-effective option.

Yes — we regularly supply replacement rollers for older Leadermac, Weinig, and SCM machines. As long as you can provide the bore, width, and diameter, we can match or replicate the original design. In some cases, we can even manufacture new cores for discontinued systems.

Yes, Leadermac feed rollers are designed to be compatible with many Weinig machines. They are precision-engineered to meet the requirements of both Leadermac and Weinig woodworking machinery, ensuring seamless integration and top-notch performance.

Leadermac feed rollers offer an excellent balance of quality and affordability. They are crafted from high-quality materials to ensure durability and long-lasting performance. When compared to other brands, Leadermac feed rollers provide competitive pricing without compromising on quality, making them a cost-effective solution for your woodworking needs.

While both Leadermac and Weinig feed rollers are excellent, Leadermac feed rollers often stand out due to their affordability, wider availability, and adaptability to various machine types. Additionally, they are manufactured to stringent quality standards, offering equal or superior performance in many applications.

You can check compatibility by referring to the specifications of your Weinig machine and the Leadermac feed roller. Alternatively, contact our team with your machine’s model number, and we’ll help you find the perfect match.

The frequency of replacement depends on usage, material processed, and maintenance. On average, feed rollers should be inspected regularly and replaced when signs of wear, such as reduced grip or uneven feed, appear. Proper care can extend their lifespan significantly.

Leadermac feed rollers are made from high-quality rubber, polyurethane, high speed steel, and other durable materials to provide optimal grip, reduce wear, and ensure smooth feeding of materials during machining.

Yes! Leadermac feed rollers are engineered for precision and durability, which minimizes downtime and ensures a consistent feed rate. Their compatibility with both Leadermac and Weinig machines can help improve the overall efficiency of your production line.

Feed rollers are commonly used in planers, moulders, and other woodworking machinery to ensure consistent material feeding. They are essential for achieving smooth finishes and maintaining accuracy in production.

Yes, Leadermac feed rollers are versatile and can be used with various woodworking machine brands, provided the specifications align. Contact us for more details on compatibility with your specific machine.

You can purchase Leadermac feed rollers directly from our website or authorized distributors. For bulk orders or special requests, reach out to our sales team for assistance.