Description

Key features

-

Continuous, controlled lubricant delivery

-

Reduces friction and minimizes wear on machine beds and guides

-

Extends the operational lifespan of machinery components

-

Prevents overheating and improves energy efficiency

-

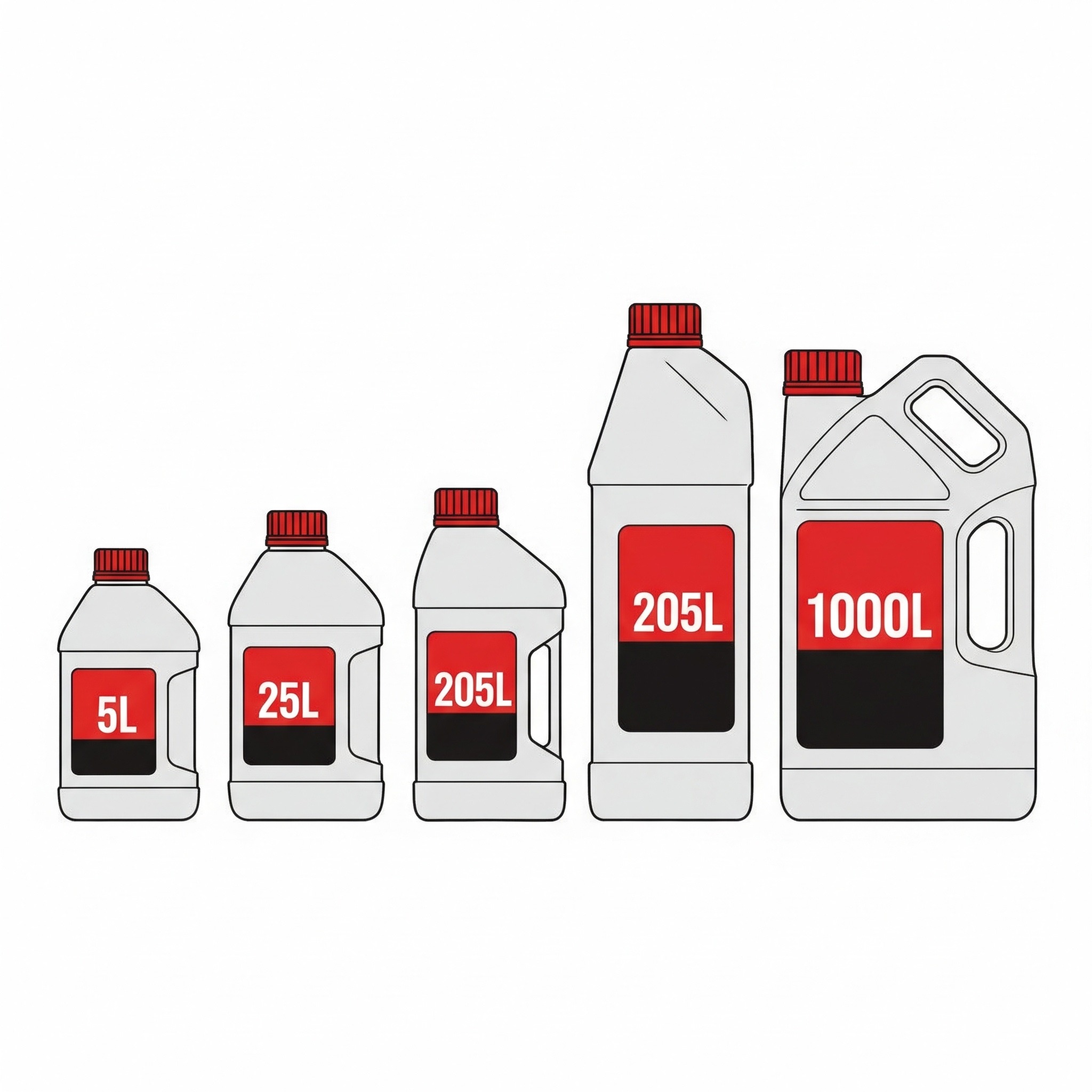

Available in multiple sizes: 5L, 25L, 205L, and 1000L

-

Customizable flow rates for precise lubrication needs

Specifications

-

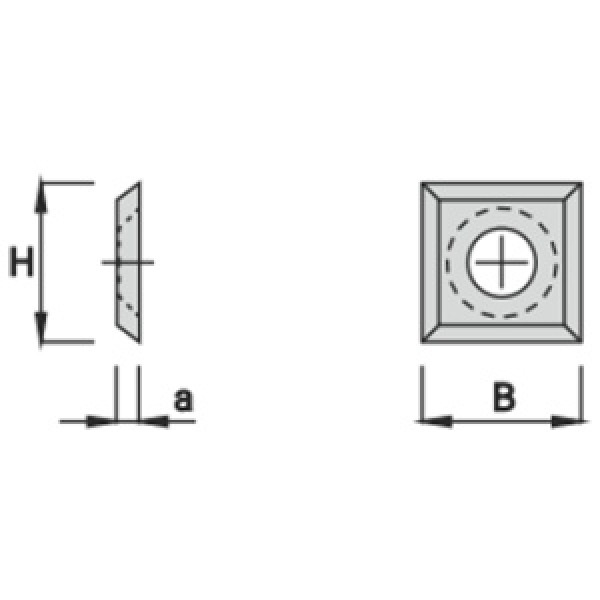

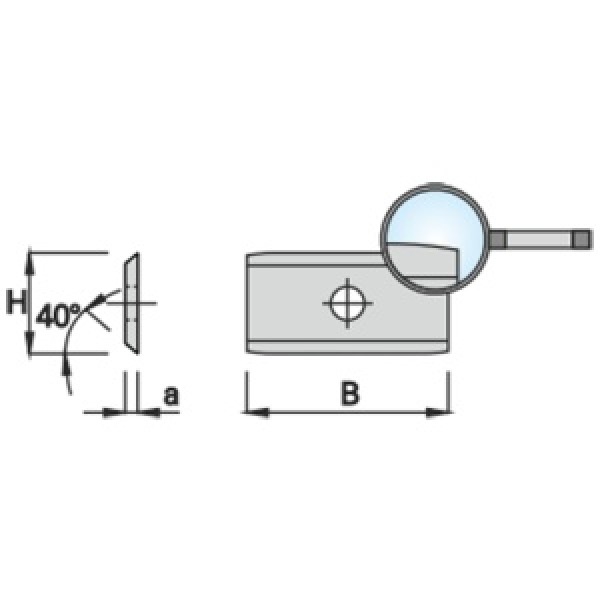

Application method: Drip feed / Gravity fed

-

Typical components: Reservoirs, drip nozzles, sight glasses, tubing

-

Media: Industrial lubricating oils

-

Common use: Machine beds, slideways, chains, guide rails

-

Benefits: Enhanced component protection, reduced maintenance

-

Available sizes: 5L, 25L, 205L, 1000L

An essential system for ensuring smooth, long-term operation of critical moving parts within woodworking machinery.